HD pellet technology

is protected as a European patent. HD® is a European Community Trademark.

HD pellet technology:

Best practice in pellet production

THE INNOVATIVE

HD TECHNOLOGY

The HD pellet technology is based on an entirely new principle. The pellets rotating on the round die are carefully cut to a defined length with the rotating movement. This is why HD pellets are not only more uniform and longer, but also more solid.

HD® makes it technically possible to produce pellets of a defined length for the first time:

The average length, length peak and maximum length can be set with millimetre precision – the system guarantees there are no over-length pellets. Only by using HD pellet technology can pellets with a length distribution which is ideal for pellet burning system be specifically produced.

LESS FRICTION AND

SCREENING LOSSE

Practical experience shows that the measurement values for friction in pellet factories on average are halved through conversion to the HD technology, and thus a significantly lower screening proportion must be fed through the production process for a second time. With values of between 0.3% and 0.8%, HD pellets are in a class of their own.

And there are significantly lower screening losses in storage and handling of HD pellets as well. The measurable and visible HD quality is retained right up to customers’ storage facilities. HD pellets also have a significantly better length distribution after blowing in. The amount of fine particles in customers’ storage facilities (<3.15 mm) is regularly less than 1%.

INSTALLATION

AND OPERATION

HD technology can be used in all standard round die presses. We undertake the individual technical conversion and installation of the HD technology.

Daily oversight and adjustment is simple and is carried out by trained production staff.

The HD quality system is integrated into the production process and builds on the existing certification programmes.

Every HD pellet manufacturer must always be certified in accordance with the requirements of DINplus or ENplus-A1. In addition, stricter requirements for the mechanical resistance are defined in the HD quality system and there are particular HD-specific parameters for length distribution.

THE INNOVATIVE

HD TECHNOLOGY

The HD pellet technology is based on an entirely new principle. The pellets rotating on the round die are carefully cut to a defined length with the rotating movement. This is why HD pellets are not only more uniform and longer, but also more solid.

HD® makes it technically possible to produce pellets of a defined length for the first time:

The average length, length peak and maximum length can be set with millimetre precision – the system guarantees there are no over-length pellets. Only by using HD pellet technology can pellets with a length distribution which is ideal for pellet burning system be specifically produced.

LESS FRICTION AND

SCREENING LOSSE

Practical experience shows that the measurement values for friction in pellet factories on average are halved through conversion to the HD technology, and thus a significantly lower screening proportion must be fed through the production process for a second time. With values of between 0.3% and 0.8%, HD pellets are in a class of their own.

And there are significantly lower screening losses in storage and handling of HD pellets as well. The measurable and visible HD quality is retained right up to customers’ storage facilities. HD pellets also have a significantly better length distribution after blowing in. The amount of fine particles in customers’ storage facilities (<3.15 mm) is regularly less than 1%.

INSTALLATION

AND OPERATION

HD technology can be used in all standard round die presses. We undertake the individual technical conversion and installation of the HD technology.

Daily oversight and adjustment is simple and is carried out by trained production staff.

The HD quality system is integrated into the production process and builds on the existing certification programmes.

Every HD pellet manufacturer must always be certified in accordance with the requirements of DINplus or ENplus-A1. In addition, stricter requirements for the mechanical resistance are defined in the HD quality system and there are particular HD-specific parameters for length distribution.

BENEFITS OF HD QUALITY

IN HANDLING

NICER PELLETS ARE ALSO BETTER PELLETS

Optimised logistics

HD pellets flow steadily and with low friction. This results in benefits even for delivery with a silo pump truck.

As HD pellets are just longer on average they have an improved “flow” in the air stream of the blowline. They are blown in with less loss.

Optimised logistics

HD pellets flow steadily and with low friction. This results in benefits even for delivery with a silo pump truck.

As HD pellets are just longer on average they have an improved “flow” in the air stream of the blowline. They are blown in with less loss.

Optimised handling

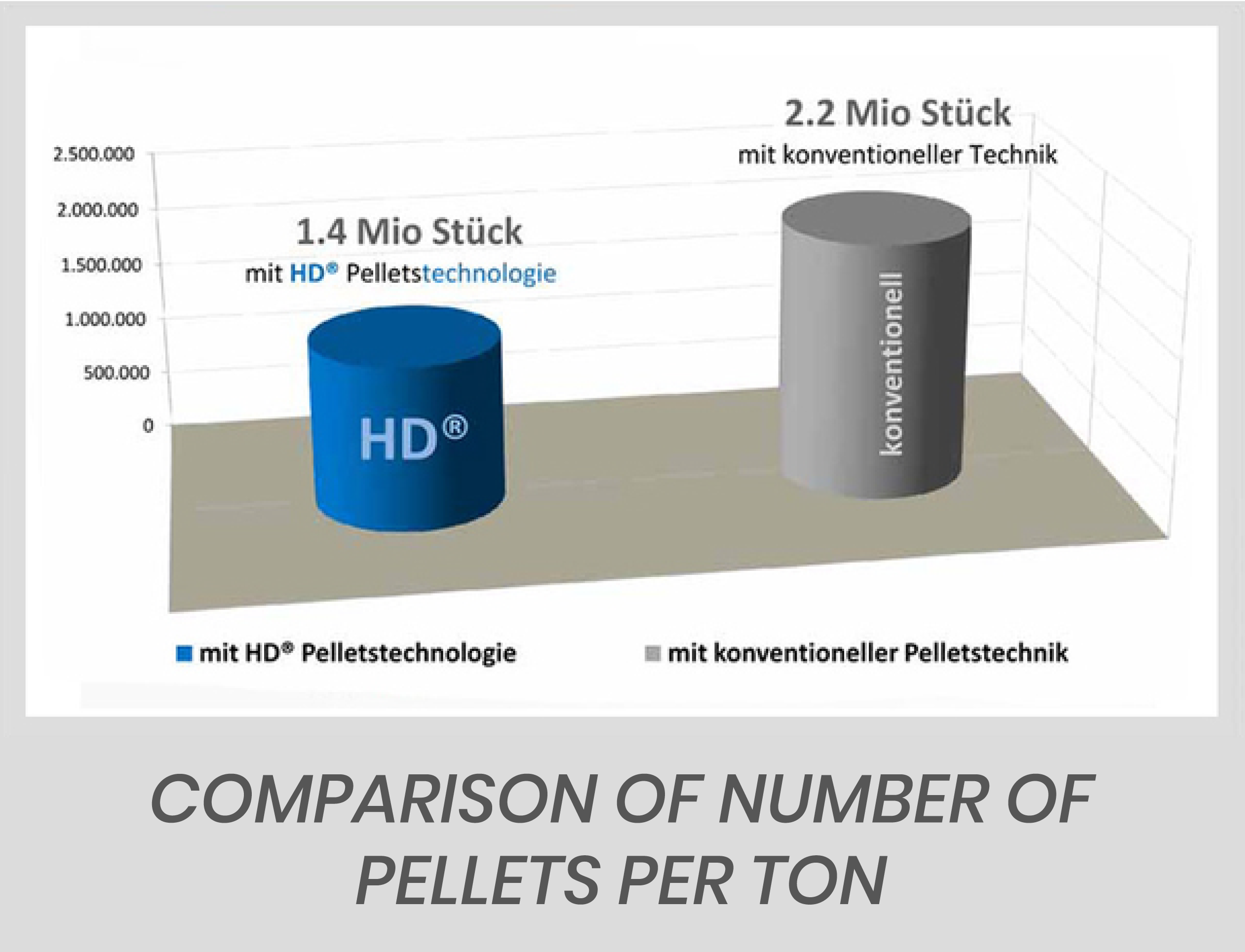

There are significantly lower screening losses in the storage and handling of HD pellets. The reason: 1 ton of HD pellets, owing to the higher average length, consists of significantly fewer individual pellets. And the end surfaces, thanks to their brittle and porous form, are the main culprits for producing fragments, abrasion and dust.

Optimised handling

There are significantly lower screening losses in the storage and handling of HD pellets. The reason: 1 ton of HD pellets, owing to the higher average length, consists of significantly fewer individual pellets. And the end surfaces, thanks to their brittle and porous form, are the main culprits for producing fragments, abrasion and dust.

Optimised quality

In addition to the particular benefits of HD quality, HD pellets are generally in better condition since the mechanical strain during the process of trimming the still hot pellets in a press runs significantly more gently. Complaints resulting from pellets which are too long are a thing of the past, guaranteed, because the maximum length of the pellets can be reliably set.

Optimised quality

In addition to the particular benefits of HD quality, HD pellets are generally in better condition since the mechanical strain during the process of trimming the still hot pellets in a press runs significantly more gently. Complaints resulting from pellets which are too long are a thing of the past, guaranteed, because the maximum length of the pellets can be reliably set.

HD TECHNOLOGY

IN USE

HD Pellets - Sifter

HD Pellets - Sifter